Who's at the base camp?

2MH Glas

The 2MH Glas GmbH, founded in 2019, has an inspiring mission: to market groundbreaking technologies for the glass industry. Our founders bring together years of experience in venture capital, international business creation and management, as well as research and development.

After successful validation, our technologies have been patented worldwide. Many international customers have already tested the improved properties in their own products. Facilities for rapid ion exchange have been ordered and will be operational later this year. Thanks to our regeneration materials, we have helped our customers avoid the replacement of salt melts and significantly improve the profitability of their companies.

These two technologies – rapid ion exchange and salt bath regeneration – will make existing glass products more sustainable and pave the way for entirely new glass products. The benefits are compelling: glasses will become more affordable, thinner, and lighter, yet more scratch-resistant and break-resistant. In just 5 minutes, rapid ion exchange achieves the same strength as the traditional process after several hours.

These technologies are suitable for almost all areas of the glass industry, from flat glass to container glass. For example, we aim to reduce solar glass thickness to just 0.7 mm. Chemically strengthened automotive glass will become the new standard with rapid ion exchange. Packaging made of thin-walled, robust glass will help reduce the plastic problem. Lighter containers will become more impact-resistant with less energy and material consumption.

With these disruptive technologies, a new chapter is being written for the entire glass industry. Be part of this sustainable change and let us together shape a better future!

AeroShield

AeroShield Materials is an MIT spinout making the world’s most transparent silica aerogels to improve the performance of insulated glass. Aerogels are some of the most thermally insulating materials ever created, they are super-light, fire resistant, and have lower embodied carbon than glass. AeroShield’s proprietary manufacturing and integration processes maintain these properties while also offering glass-like transparency.

When bonded to glass, the aerogel acts like a macro coating that can dramatically improve the U-Value of glass products. It is compatible with existing spacer and framing systems, and can be incorporated into existing gap thicknesses.

A thicker aerogel provides more insulation, meaning it can be tuned to hit different performance targets across a portfolio of products and future-proofs against further changes in building codes, incentive programs, and more.

Learn why AeroShield is the clear choice for window insulation: https://www.aeroshield.tech/

eLstar

eLstar Dynamics is a leading developer and provider of adaptive smart glass for a wide range of applications such as architecture, automotive and specialty markets. eLstar addresses the needs for attainable solutions by offering sustainable and affordable smart glass. By using existing manufacturing facilities, eLstar is able to produce smart glass with much lower energy and impact to the environment.

Hypermemo

Hypermemo develops the most advanced laser technology (GlaserTM) for industrial glass processing. The core innovation of Hypermemo is a proprietary short-pulsed CO2 laser featuring extra-high peak power. GlaserTM enables processing of any common types of glass, with thickness up to 12 mm, in one pass. Glass is self-separated and has clear and stress-free edge. This dramatically improves edge strength and in many cases makes post-processing obsolete. In addition, it helps decreasing the equipment footprint and thus improves ROI, enabling sustainable transformation of the industry.

IR Dynamics

IR Dynamics, Inc. is a technology company established in 2014 that has been developing a solution to make windows more energy efficient using thermochromic nanoparticle technology to control solar heat gain. The Company has succeeded in developing a high-performance, low-cost coating for glass that will reduce heating and cooling costs in residential and commercial buildings. IR Dynamics technology can also be used in energy efficiency window films to retrofit existing windows.

“Lowering the cost to heat and cool buildings while reducing CO2 emissions is the goal for this technology”

Li3

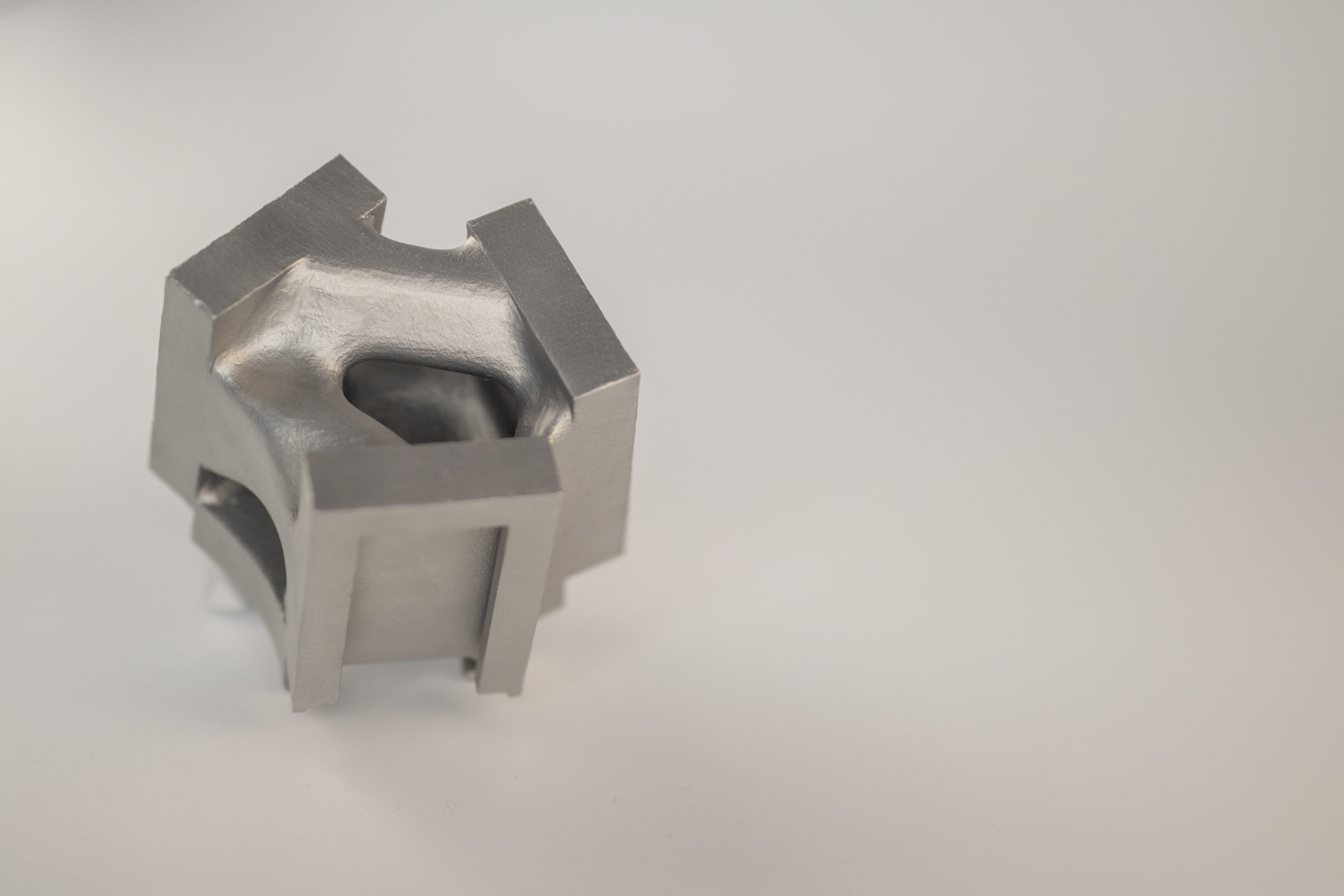

Lithium Designers GmbH is a group of Architects, Engineers, and Researchers. Their business idea is to minimizes the planning effort and manufacturing costs of freeform facades. To achieve this, Li3Designers employs modern techniques not currently established in the construction industry, creating a new market position. No other company worldwide can offer automated freeform facade planning. Additionally, the implementation of in-house 3D-printed nodes is also unique worldwide. 3D-printed components have not been used in construction worldwide so far. Li3Designers has found a use case for 3D printing in construction and developed a product that maximizes its potential. Li3Designers offers complete facade planning, from conceptual design to detailed construction, including engineering and subsequent on-site supervision. Due to the wide range of planning services, Li3Designers’ role can be adapted to the construction project. They can take on all planning services or, for example, only the role of an architect, facade planner, or consultant.

MIMSI Materials

MIMSI Materials is a deeptech company based in Linköping, Sweden. We are developing a platform technology for creating a new class of high-performance transparent materials based on precision silver alloys. Our first material Alumenate®, which was recently launched, extends the optical, electrical, durability and sustainability performance beyond the limits of state-of-the-art low-e coatings. Alloying agents are strategically introduced to silver during the magnetron sputtering deposition process, providing unprecedented possibilities to control the thin film growth. The optionality of our deeptech innovation enables our materials to be tailored to other applications requiring transparent conductive coatings, such as photovoltaics and AR/VR headsets.

Miru

Miru Smart Technologies is developing next-generation electrochromic window (eWindow) solutions for the residential, commercial and automotive markets. Miru is disrupting how eWindows are produced and distributed, with a patented process that lowers costs, improves performance and significantly reduces embedded and operational carbon emissions—enhancing the well-being of people and our planet.

Miru has tailored our manufacturing process and business model to operate within existing fenestration manufacturing channels. We make electrochromic technology simple to manufacture and distribute by working closely with glass fabricators, installers and builders.

“Be a part of the smart window revolution. Learn more at www.mirucorp.com and follow Miru on LinkedIn

Peafowl Plasmonics

There are countless possible applications where our transparent light harvesting cells can make a significant difference by adding a self-powering capacity to innumerable digital functions in our environment to simplify and elate our every-day life. Dynamic windows can make a huge impact on how window glass can add functionality by tinting the glass, to block sun or heat. This functionality, combined with indoor sensors, can make buildings really smart and save a lot of energy.

Tynt

Tynt is a new way to experience natural light at home. We make elegant, ultra climate-friendly windows that adapt to your changing needs throughout the day.

Windows are often the leakiest place in a home. They are responsible for an astonishing 30% of heating and energy loss. For anyone looking to green their home and save money on energy costs, Tynt provides a far better return than solar. Our windows pay for themselves in as little as 2 years.

With the touch of a button, our windows welcome brilliant natural light at every level of shade with precise glare control. Unlike electrochromic solutions, there are no synthetic blue and yellow tints or screen-like filtering effects with Tynt.

Our patented technology lets homeowners quickly adjust visible light from crystal clear all the way to our exclusive blackout. It’s a smooth, elegant transition, like clouds gliding past the sun – just as mother nature intended.

Tynt windows can be programmed to your unique lifestyle. Whether you’re optimizing for comfort, privacy, or energy efficiency, the ideal setting is seconds away.

Our energy efficient window technology, Reversible Metal Electrodeposition (RME), was developed at Stanford University and the University of Colorado Boulder, supported by the Department of Energy. It uses metal films to control the light and heat flow, and requires less than one volt to function.

We work with residential builders and homeowners to bring the most advanced and climate-friendly windows into homes across the country. To learn more and experience the Tynt difference, please visit https://www.tynt.io/.

Tynt. Light that lives with you.

VideowindoW

VideowindoW is an award-winning technology startup, creating a new market segment by transforming glass façades into versatile and transparent media platforms. Immersive entertainment is combined with glare control and climate control. VideowindoW is already installed in airports where commercial content instantly yields a return on investment. ‘Shading as a Service’ that pays for itself. VideowindoW helps customers to achieve sustainability goals in a fun and profitable way. VideowindoW is headquartered at ‘YES!Delft’, the Tech Incubator at Delft University, The Netherlands. Among its launching customers are Amsterdam Airport Schiphol and Rotterdam The Hague Airport. Multiple patents are granted or pending. Follow us on LinkedIn, or for more information, visit our website.

Volframi

Volframi Oy manufactures equipment and develops methods for various partial processes for glass industry. Our company has strong in-house expertise from various sectors of the vacuum processes, coating, equipment and process design, glass processing industry and intellectual property rights.

We have introduced a new vacuum coating process without the traditional limitations of glass and equipment size. This innovative process allows us to make targeted coatings and processes on a glass pane without processing the entire area. Volframi´s completely new way of handling glass allows the addition of new functionalities, making some existing functions easier and more feasible. Processes and activities from different industries can be combined in a specific framework to create completely new and competitive solutions for the glass processing industry. Our purpose is to provide scalable solutions for partial surface processing.